In the factory of a customer of Dongguan Sirui Machinery Manufacturing Co., Ltd., a standardized recycled cotton production line is operating efficiently - from sponge scraps to finished product cutting, only four core equipment are needed to complete the entire production process.

1. SR-C03 Sponge Crusher (Strong Type): Efficient Crushing of Sponge Particles

As the first process of the recycled cotton production line, the sponge crusher crushes all kinds of hard and soft sponge scraps, rags, and yarn ends into particles. The waste can be crushed into particles of different sizes by replacing screens of different sizes, providing standardized raw materials for subsequent mixing processes.

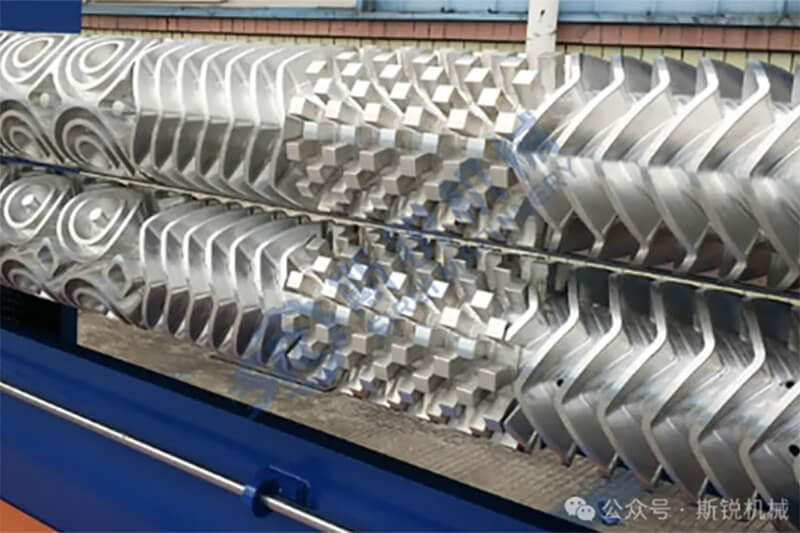

2. SR-R Series Recycled Cotton Machine: Core Equipment for Mold Oil Pressure Forming

The crushed sponge particles are mixed with glue and then sent to the main mold box of the recycled cotton machine. The equipment adopts a hydraulic oil pressure system, which is pressed into recycled cotton of the corresponding required density by the oil pressure system. The standard configuration single mold box model realizes the automation of the entire process of stirring, mixing, pressurizing, and forming. Enterprises can also choose dual-mode boxes, automatic feeding or electronic weighing systems according to production capacity requirements. The steam function is a value-added option, which can increase production efficiency by 6-8 times, and provide additional protection for customers with high productivity and sterilization requirements.

3. SR-V/SR-H series sponge straight cutting machine and flat cutting machine: efficient finishing

The formed recycled sponge needs to go through two finishing processes: the sponge straight cutting machine quickly cuts off irregular burrs to make the product edge flat; the sponge flat cutting machine can complete the sheet cutting of block sponge at one time, and can cut different sheet thicknesses according to requirements for sofas, mattresses, packaging, etc. The two devices are used together to ensure the uniformity of the finished product size.

If you need to reprocess sponge waste, the Si Rui Machinery Reproduction Sponge Production Line can provide you with ideal production equipment. Dongguan Sirui Machinery is a sponge machinery manufacturer that produces and sells the SIRUI brand. It provides on-site layout, installation, commissioning, training, maintenance and other services. Its products are exported to Europe, America, Southeast Asia and Africa. The service hotline is: 0769-83000805. Learn more and we will provide you with the customized solutions you need.