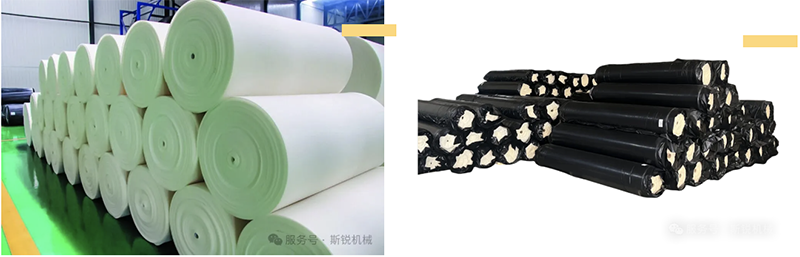

Have you ever been troubled by the storage and transportation of sponge products?

Traditional sponge rolls, due to their large volume and unique shape, not only occupy a large amount of storage space, but also result in low loading rates for transportation vehicles. Don't worry, today we are going to introduce the equipment - the fully automatic roll cotton baler, which will completely solve these troubles!

Say goodbye to the era of "bloated" and embrace intelligent packaging

Imagine this: a super large sponge roll with a diameter of 1.5 meters, instantly transformed into a compact size of only 0.5 meters through intelligent compression by a roll packing machine! This is not magic, but the sponge optimization solution we bring to you.

SR-RC03

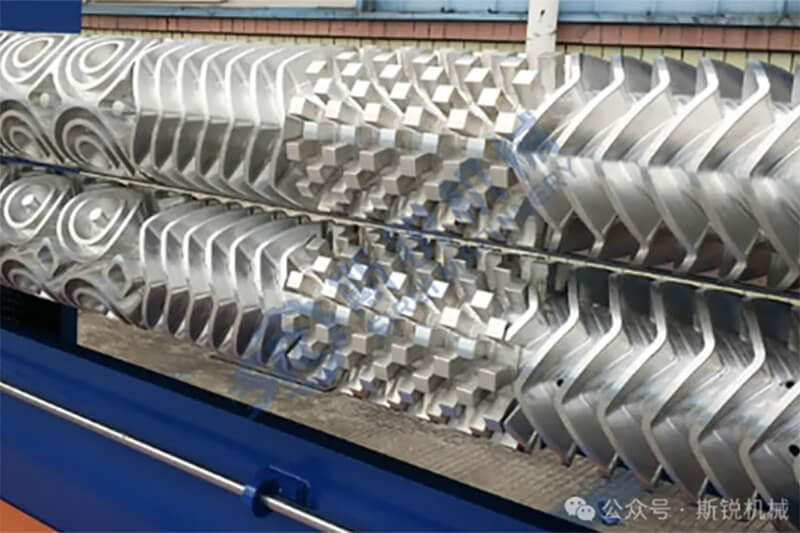

By adopting advanced hydraulic compression system and intelligent control technology, the diameter of 700-1500mm roll cotton can be compressed to 350-750mm, with a volume reduction of over 50%. The equipment integrates automatic feeding, film wrapping, double-layer heat sealing and precise cutting functions, achieving full automation of the packaging process.

Technical Specifications

Applicable width: 1000-2300mm

Pre roll diameter: 700-1500mm

Diameter after coiling: 350-750mm

Packing efficiency: 30-40 rolls/hour (adjustable)

Three major changes to help sponge manufacturing enterprises reduce costs and increase efficiency

1. Significantly improve storage space utilization

By strong compression and regular packaging, the volume of the rolled cotton can be reduced to over 50% of its original size. The warehouse, which originally could only store 10 rolls, can now accommodate more than 20 rolls, doubling the space utilization rate, especially suitable for enterprises with limited storage capacity.

2. Significantly reduce transportation costs

Volume compression means an increase in the number of products that can be transported in a single shipment, thereby diluting the logistics cost per unit of product. Whether it is domestic delivery or export packing, it can save shipping costs by more than 40%, especially for e-commerce and foreign trade enterprises, the cost control effect is immediate.

3. Automated operation, efficient, stable and labor-saving

Fully automated operation means that there is no longer a need for a large amount of manpower to perform the heavy sponge packing work. By setting the parameters, the equipment can operate stably and help production managers accurately control the progress of their work.

If you are troubled by these things

Sponge warehouse is always not enough

High transportation costs

The packaging efficiency cannot keep up with the order volume

The product is prone to damage during transportation

So, the SR-RC03 fully automatic cotton strapping machine may be the solution you are looking for!

If you have a need to optimize the storage, packaging, and transportation of sponges, the Sirui Mechanical Roll Sponge Packaging Machine can provide you with an ideal sponge compression and packaging solution. Dongguan SIRUI Machinery is a sponge machinery manufacturing enterprise that produces and sells SIRUI brand products. We provide on-site layout, installation, debugging, training, maintenance and other services. Our products are exported to Europe, America, Southeast Asia and Africa. Our service hotline is 86-13450688517. Learn more information and we will provide you with the customized solution you need.