As a sponge manufacturer, do you often face these challenges?

The warehouse becomes increasingly full as it piles up, and long sponge strips occupy a large amount of flat space, resulting in low turnover efficiency

Manual handling is time-consuming and labor-intensive, and the storage and retrieval efficiency cannot keep up with the production pace

Traditional storage methods can easily cause sponge deformation and wear, affecting product quality

SR-BSU sponge three-dimensional storage system, specially designed for sponge manufacturers, uses intelligent sponge three-dimensional storage solutions to increase your storage efficiency by 300% and reduce labor costs by 50%!

Pain points vs. solutions

The drawbacks of traditional sponge storage

Flat stacking, low space utilization rate

Manual handling has low efficiency and is prone to errors

Sponge is prone to deformation under long-term pressure

Intelligent upgrade of SR-BSU sponge three-dimensional storage (supporting customization)

1. Multi layer stereoscopic storage doubles space utilization

Customize an exclusive sponge storage system solution for you based on the factory layout

Small footprint, with storage capacity three times that of traditional warehouses

2. Fully automatic conveying, saving manpower and effort

Automated collaboration of conveyor line and elevator ensures precise sponge delivery to the desired location

The operator only needs to set the parameters on the touch screen, and the system will automatically complete the access

3. Professional design to protect sponge quality

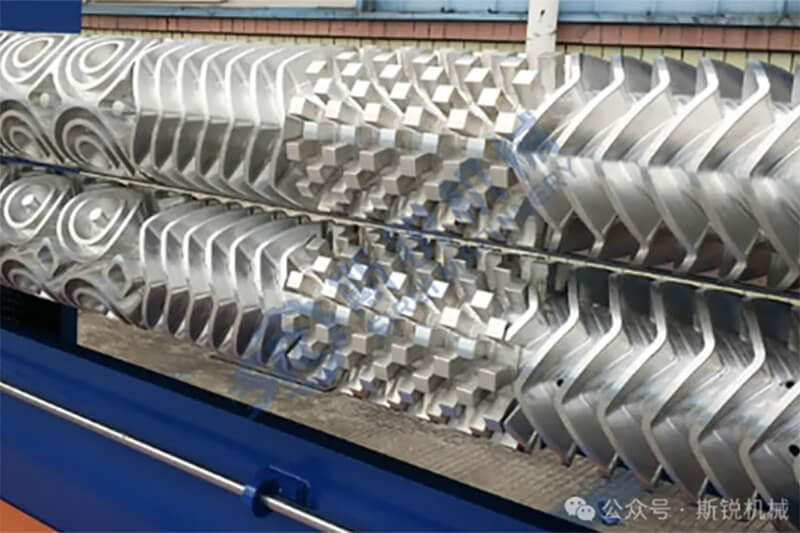

400mm drum spacing+250mm wide belt for smoother support

Avoid squeezing deformation caused by manual handling

Why are peers using sponge three-dimensional storage?

Cost reduction: Reduce warehouse manpower demand by 50%

Efficiency improvement: Access speed increased by 3 times, seamless integration with production lines

Expansion: With the same area, storage capacity increases by 300%

Why choose SR-BSU sponge three-dimensional storage?

1. Intelligent synchronization, one click operation

Through an automatic synchronization control system, the mobile conveyor line and lifting platform work together. With simple parameter settings, the system can accurately transport and position sponges, greatly reducing manual intervention.

2. Flexible customization, efficient use of space

Tailored according to sponge length and storage capacity, the vertical space utilization rate is increased by over 300%.

3. Stable and reliable, quality assurance

The core components adopt Mitsubishi PLC, Delta touch screen/frequency converter, and Schneider Electric components to ensure long-term stable operation of the system.

The drum spacing is 400mm, and the belt conveyor platform provides precise support to prevent sponge deformation or wear.

After a medium-sized sponge factory introduced the SR-BSU system:

Reduce storage area by 60%

Daily shipment volume doubled

The product loss rate has decreased by 35%

In today's fiercely competitive sponge industry, warehousing efficiency is the core competitiveness

SR-BSU uses intelligent sponge three-dimensional storage solution to help you:

Save more production space

Outperform peers in terms of shipping speed

Maintain the bottom line of product quality

If you have a need for sponge storage and transportation, Sirui Mechanical Sponge Storage can provide you with an ideal transportation and storage solution. Dongguan SIRUI Machinery is a sponge machinery manufacturing enterprise that produces and sells SIRUI brand products. We provide on-site layout, installation, debugging, training, maintenance and other services. Our products are exported to Europe, America, Southeast Asia and Africa. Our service hotline is 86-13450688517. Learn more information and we will provide you with the customized solution you need.