Whether it is a large factory assembly line or a small startup factory customization, Sirui recommends suitable foaming machines for you according to different scale enterprises. Let's briefly talk about their "special skills"~

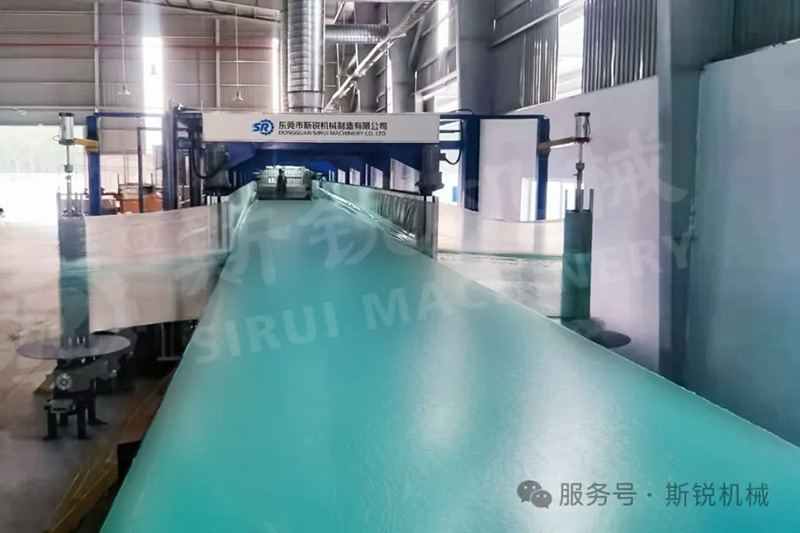

1. SR-HCF sponge horizontal continuous foaming production line

Applicable groups: large production plants | remote control | density 4-180kg/m³ | 13 foaming components

The sponge horizontal continuous foaming production line is suitable for large factories that produce polyurethane soft foam in large quantities and in a standardized manner, and have high requirements for sponge output, quality, and production efficiency, such as mattress and furniture manufacturers.

Core advantages:

▶ Assembly line production, high sponge foaming output, automated production saves labor;

▶ Automated human-machine interface control system, flexible adjustment of production parameters, switching formulas only requires a click on the screen;

▶ Remote control function, more scientific and intuitive control of production costs, suitable for large-scale standardized production.

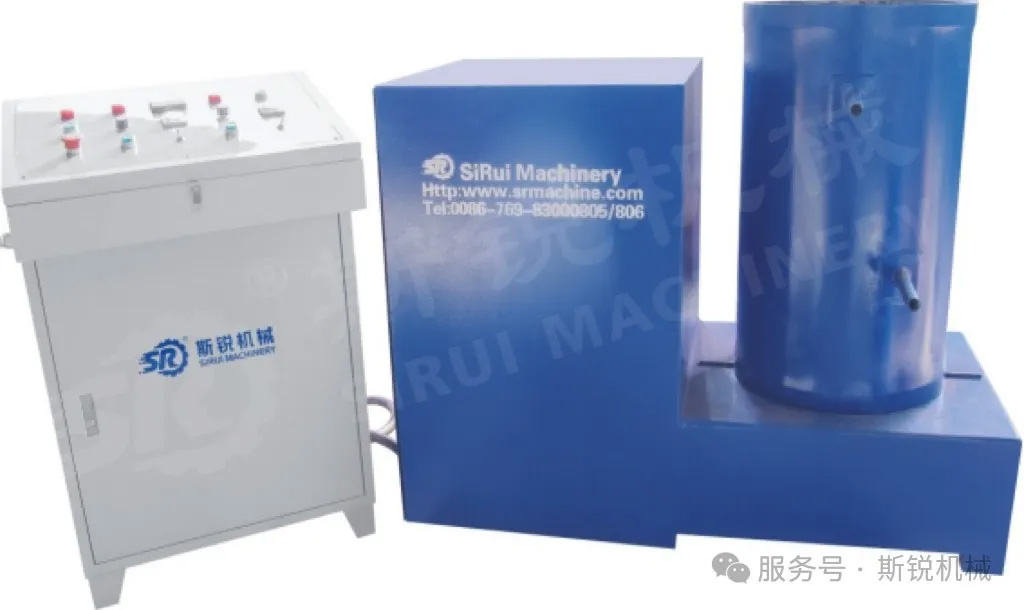

2. SR-SAFO1 automatic box-type foaming machine

Suitable for: small and medium-sized enterprises | flexible order acceptance | density 8-80kg/m³ | 3 foaming components

Automatic box-type sponge foaming machine is suitable for small and medium-sized factories, such as those specializing in furniture, packaging lining or auto parts, with moderate order volume but diverse types.

Core advantages:

▶ Small size, can be placed in the corner of the workshop, different mold sizes can be selected according to production needs;

▶ Intelligent touch screen control system formula can be adjusted at any time, one-click switch different foaming densities and raw material combinations;

▶ Adapt to molds of various sizes to adapt to the production of products of different specifications;

▶ Easy to operate, with automatic computer control and manual dual-use control functions.

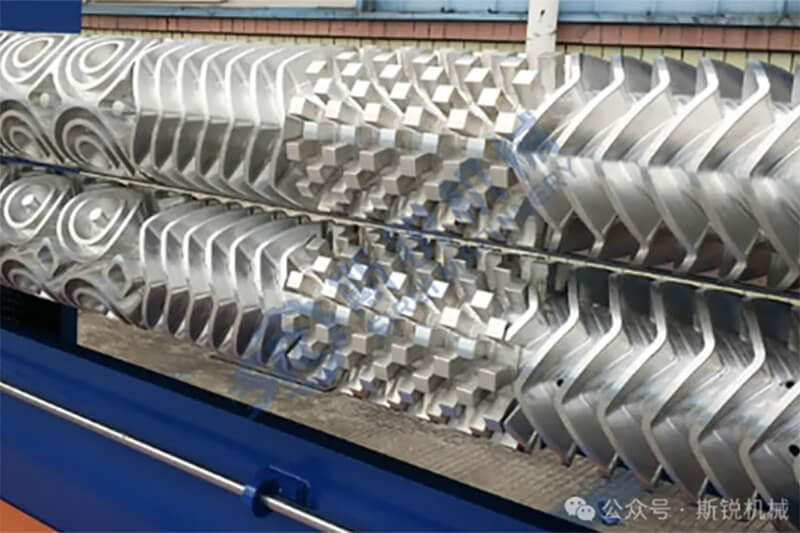

3. SR-FH/FV series manual foaming machine (pedestal/vertical)

Suitable for: small entrepreneurial factories | Newbie-friendly | density 8-80kg/m³ | 180 kg foaming volume

Suitable for small factories that are just starting out or taking personalized orders, such as customizing small household items, sponge fillings, etc.

Core advantages:

▶ Simple manual operation, pouring → mixing → discharging, done in three steps;

▶ The seated type is easy to move, the vertical type saves space, and you can choose any type according to the layout of the workshop;

▶ It has a timing function, which can accurately control the setting of the mixing time.

How to choose in one sentence

◆ Large factory with many orders → Choose SR-HCF, automated assembly line;

◆ Small factory with miscellaneous work → Choose SR-SAFO1, flexible order switching;

◆ Just starting out/customizing → Choose SR-FH/FV manual model, low-cost trial.

If you need to produce sponge foaming, SIRUI Machinery's various sponge foaming machines can provide you with ideal production equipment. Dongguan SIRUI Machinery is a sponge machinery manufacturing company that produces and sells the SIRUI brand, providing on-site layout, installation, commissioning, training, maintenance and other services. Its products are exported to Europe, America, Southeast Asia and Africa. Service hotline: 0769-83000805. Learn more and we will provide you with the customized solutions you need.