In the field of vertical cutting of sponges, precision and efficiency directly affect product quality and production costs. With its excellent performance, the SR-V series sponge straight cutting machine can easily handle the processing of materials such as sponges, EVA, pearl cotton or honeycomb cotton.

The sponge vertical cutting machine has stable performance and simple operation. It is a good helper for many factories to improve efficiency and control costs; this article will take you to have a deep understanding of the various advantages of this sponge straight cutting machine.

01. The core advantages of professional design

Accurate cutting with small errors

The SR-V sponge vertical cutting machine series track adopts T89 elevator guide rails and is precisely processed to ensure smooth operation without deviation;

High-precision cutting, the minimum cutting thickness can reach 2mm, and the error is controlled within ±0.5mm;

Equipped with an automatic sharpening system to ensure that the blade remains sharp and unobstructed for a long time;

Equipped with a knife guard device, which can be freely adjusted according to the height of the cutting product, which can not only protect the safety of the operator but also prevent the knife belt from shaking, and the cutting is more stable.

Stable structural design, stable for ten years

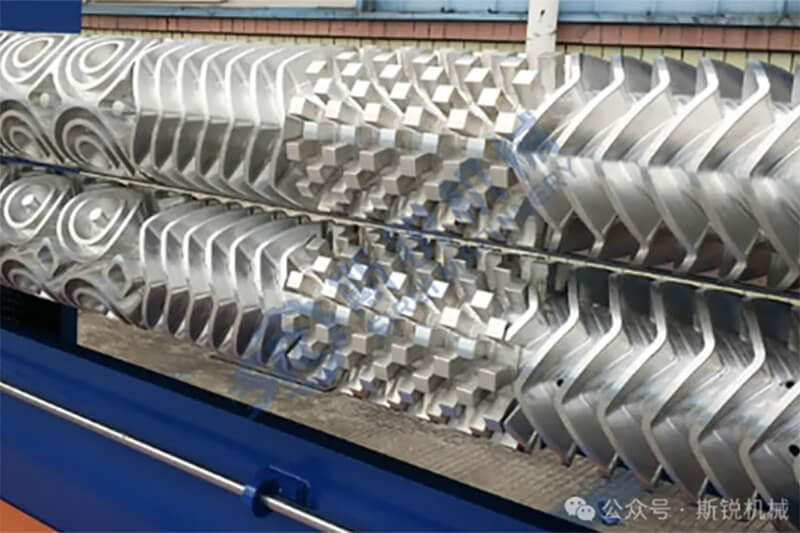

The blade wheel of the sponge vertical cutting machine is finely processed and balanced, and the surface is coated with special materials, which is low noise and wear-resistant;

The workbench adopts a composite structure of 8mm industrial-grade plywood and 4mm aluminum-plastic plate, which is strong and durable and not easy to deform;

The frame adopts a thickened steel structure, which is stable and has a longer service life;

The baffle movement adopts linear guide transmission equipped with imported bearings, which slides more smoothly and has smaller deviations, effectively preventing offset or vibration during cutting, and maintaining long-term high-precision operation capabilities.

2. Detailed explanation of professional size specifications

SR-V02 medium-sized sponge vertical cutting machine

Inner workbench size: 1320×2440mm

Outer workbench size: 1200×2440mm

Maximum cutting height: 1200mm (customizable)

SR-V03 large sponge vertical cutting machine

Inner workbench size: 1720×2440mm

Outer workbench size: 2000×2440mm

Maximum cutting height: 1200mm (customizable)

3. Professional application scenario analysis

Multi-material adaptation

Sponge material

EVA foam material

Pearl cotton

Honeycomb cotton

Industry application

Furniture manufacturing: sofa, mattress sponge cutting

Packaging industry: precision packaging material processing

Automotive interior: seat, sound insulation material molding

Sports goods: sports protective gear, yoga mat production

4. Professional customization service of sponge straight cutting machine

Workbench size and cutting height can be customized as needed

Optional knife belt types, such as ordinary knife belt, twist knife, serrated knife, etc.

Optional automatic lifting device for knife guard

Motor power customization, cutting high-density and high-hardness materials is preferred

Optional safety fence protection device

If you need to perform sponge cutting processing, SIRUI Machinery's various sponge cutting machines can provide you with ideal production equipment. Dongguan SIRUI Machinery is a sponge machinery manufacturing enterprise that produces and sells SIRUI brand, providing on-site layout, installation, commissioning, training, maintenance and other services. Its products are exported to Europe, America, Southeast Asia and Africa. Service hotline: 86-13450688517. Learn more and we will provide you with the customized solutions you need.