Among the many sponge processing technologies, parallel sponge cutting is a basic and key step. Its goal is simple and clear: to accurately, efficiently and stably "decompose" a thick whole sponge into thin slices of uniform thickness. This seemingly simple action is an important link in determining the sponge utilization rate, product performance and final value.

However, facing different scenarios such as continuous long materials, independent blocks, batch requirements, ultra-thin challenges, how to ensure that each "decomposition" is stable and reliable, and the output is uniform and consistent? This requires not only sharp tools, but also targeted professional solutions.

1. SR-H sponge flat cutting machine: "Stable and reliable pragmatism"

Designed for: daily slicing needs of conventional block sponges.

Core advantages:

Simple and efficient operation: set the thickness, and the workbench automatically goes back and forth after startup. The process is simple and easy to use.

Wide range of cutting thickness and density: according to different sponge types and sponge densities, the thickness can be flexibly set (such as 2-200mm), and the cutting density can reach about 200kg/m³.

Stronger cutting stability: Anti-slip sandpaper work surface and pressure roller device effectively prevent sponge displacement during cutting, ensure smooth cut surface and reduce errors; optional suction device can also be equipped to provide more stable sponge fixation.

2.SR-HT sponge rail flat cutting machine: "Essential supporting equipment for continuous foaming line"

Specially designed for: efficient slitting of long sponges produced by continuous foaming production line.

Core advantages:

Intelligent control system: Equipped with dual control system, button or touch screen operation interface can be selected, intuitive operation and flexible parameter setting.

Track-level smooth operation: The machine automatically cuts back and forth on the rail, runs smoothly, eliminates fluctuations in long-distance cutting, and ensures the thickness consistency of the entire sponge from beginning to end.

High cutting accuracy and strong repeatability: With high-precision coder and servo system, high-precision control of plus or minus 0.5mm is achieved, and continuous large-scale cutting can be achieved, with uniform thickness of each layer and thin bottom (thinnest 8mm).

Seamless connection production line: ideal choice for continuous operation. Optional automatic material collection, trimming, and mesh belt worktables to achieve a smoother "cutting-collecting" process.

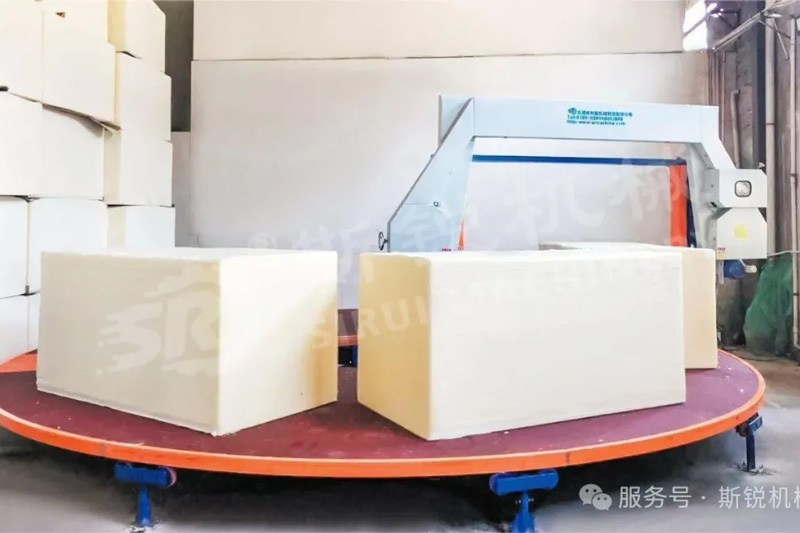

3. SR-HC Sponge Disc Flat Cutter: "Master of Multi-tasking"

Designed for: cutting multiple pieces of block sponges at the same time to increase production capacity.

Core advantages:

Rotary table continuous operation: The circular table rotates 360 degrees continuously, and multiple sponges can be cut in batches without interruption, significantly increasing the output per unit time.

Flexible and controllable speed: The rotation speed can be freely adjusted according to material properties and production needs.

Stable guarantee: Optional suction device or pressure roller device can effectively absorb or press the sponge to prevent sliding or warping during cutting, ensuring the cutting accuracy and edge quality of each sponge in batch operation.

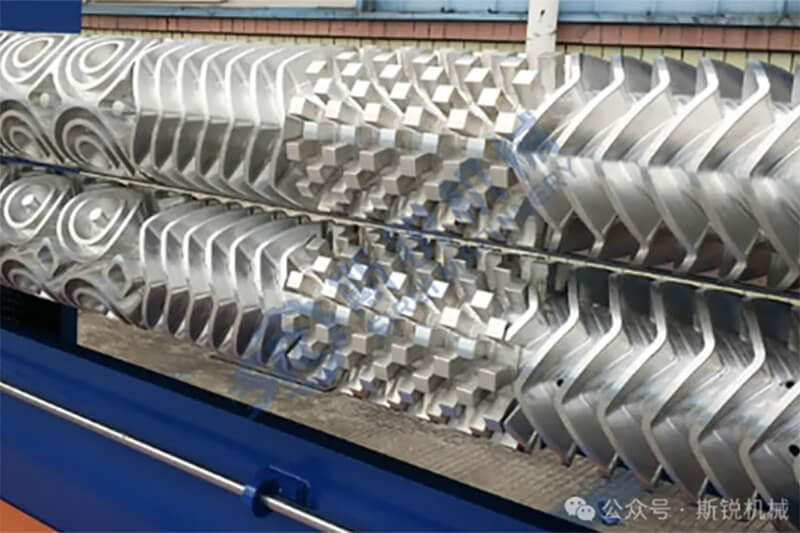

4. SR-HPV High-precision Vacuum Flat Cutter: "The ultimate solution to challenge 1mm ultra-thin precision"

Designed for: Strict precision requirements, especially for ultra-thin sheet (such as 1mm) slitting tasks.

Core advantages:

Double locking, motionless: special wooden platform + strong suction system produces super strong adsorption force; equipped with thick knife box, strong knife belt stability, and precise pressure roller synchronous pressure, completely eliminate any tiny displacement during cutting - this is the key to achieve ultra-thin precision.

Precision control, stable output: ball screw is used for lifting and lowering, parameters are set according to thickness and density, and the machine cuts back and forth on high-precision linear guide rails.

Challenge the thickness limit: specially designed for stable output of extremely thin and highly consistent sheets of 1mm and above.

Summary in one sentence:

H series is reliable for conventional block cutting; HT is selected for continuous cutting of long materials; HC is used for synchronous cutting of multiple blocks; HPV is responsible for ultra-thin precision cutting.

If you need to carry out sponge cutting processing, Sirui Machinery's various sponge cutting machines can provide you with ideal production equipment. Dongguan Sirui Machinery is a sponge machinery manufacturer that produces and sells the SIRUI brand. It provides on-site layout, installation, commissioning, training, maintenance and other services. Its products are exported to Europe, America, Southeast Asia and Africa. The service hotline is: 86-13450688517. Learn more and we will provide you with the customized solutions you need.