The sponge foaming line is a large-scale foaming machine, suitable for soft polyurethane sponges with a density of 4-180kg/m³. There are many types of sponges produced, such as furniture foam, memory foam, high resilience foam, vigorous foam, shoes Material foam and etc. Our sponge foaming line is neither high pressure nor low pressure, it is a normal air pressure sponge foaming line.

The sponge components required for the production of different sponges by the sponge foaming line are also different, and different chemical raw materials need to be used. The basic sponge chemical raw materials are PPG, POP, TDI, MC, silicone oil, A33, T9, and then according to the production. The type of sponge adds other raw materials; the standard sponge foaming line is 13 components, the total length is about 44 meters, the workshop length is 55-60 meters, and the width is 8 meters is the best, the so-called one component of the sponge foaming line What is included? From the feeding system-stirring system-constant temperature system-loading system-foaming system-programming control is a complete component, and all of them are indispensable and complement each other.

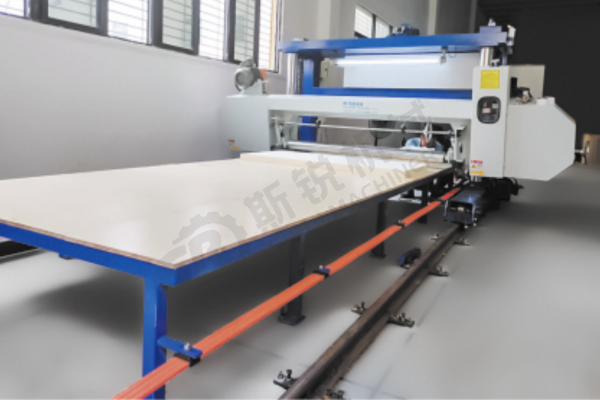

The sponge foaming line is mainly divided into four parts, one is various material tanks, which are used to store different chemical raw materials, such as PPG, TDI, etc., the second is the control platform, which mainly controls all the actions of the entire sponge foaming line, and the third is Mixing head, mix all the given amount of raw materials in the mixing head, the third is the oven, the standard oven length of the sponge foaming line is 18 meters. , The fourth is the block cutting machine, which cuts different sponge blocks according to the required length of the sponge.

The maximum length can be cut to 6 meters. If a longer sponge is required, it needs to be added to the rear end of the foam foam line. The length of the rear conveyor line is customized according to the required length of the sponge.

Tips: After the sponge foam production line is completed, it needs to be placed in a ventilated place for about 8 hours before processing.