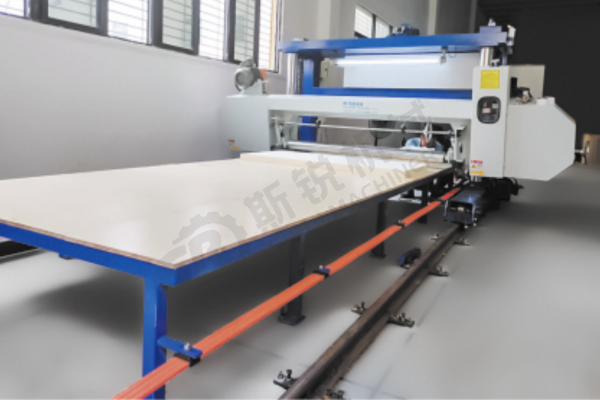

The automatic box batch foaming machine is suitable for small and medium-sized sponge production enterprises that are just starting out. It is suitable for soft polyurethane sponges with a density of 4-180kg/m³. There are many types of sponges produced, such as furniture foam, memory foam, high resilience foam, etc. The principle of Automatic box batch foaming machine is to store the required raw materials (PPG, POP, TDI and other auxiliary agents) in the storage tank after temperature control, and then send them to the high-speed by several groups of precision metering pumps according to a certain proportion. In the stirring mixing head, under high-speed stirring, it is quickly mixed evenly and solidified to form a flat-topped square or round sponge, which takes an average of 8-10 minutes for one bubble. If you want to increase the output, you can add several sets of molds.

The main equipment system of box batch foaming machine:

1. Storage system

The storage tank of Automatic box batch foaming machine is mainly made of carbon steel or stainless steel. Different material tanks are configured according to different types of sponges. The main material tanks such as PPG, POP, and TDI are equipped with a stirring device and a constant temperature coil to control the raw materials. Temperature, thermometer, liquid level gauge and other devices are used, and gear pump is used for feeding, and a filter device is installed at the inlet of the tank.

2. Metering system

Automatic box batch foaming machine adopts a high-precision metering pump, and the precise flow rate suitable for different densities is obtained through frequency conversion speed regulation, and the rotational speed or frequency during foaming can be visually displayed on the electric control cabinet. The flow can be adjusted in the control cabinet screen .

3. Electronic control system

Automatic box batch foaming machine mainly adopts imported electrical components, computer programming, and easy operation. The flow rate of each component can be fine-tuned at any time during the foaming process.

4. Mixing system

The mixing head of Automatic box batch foaming machine is one of the important parts of the whole production line. The mixing barrel adopts pneumatic automatic switch, which has the characteristics of novel structure, uniform mixing and wide range of applicable densities.

Dongguan Sirui Machinery Manufacturing Co., Ltd is "SR " brand, provide site layout, installation, commissioning, training, maintenance and other services for customers, the company products in the international advanced level, have been exported to Africa, Americas, Europe and Southeast Asia and many other countries and area, Tel: 0086-0769-83000805/806。