Technical

Technical2020-04-28

Sponge machine packaging and handling

The machine has been reasonably disassembled and packaged when it leaves the factory. When the machine is lifted, it should be operated according to the requirements and shape of the packaging box. The transportation process should avoid the deformation of the machine. ), Check the outside of the package for damage before opening the package....

Read More Technical

Technical2020-04-28

Cleaning and maintenance of sponge machinery

Rolling bearings are used for rotating electrical machines. The bearings should be cleaned (using kerosene or diesel) every other month. The bearings should be replaced with clean grease. Gears, sprockets, etc. should be cleaned of oil before work every day and then lubricated....

Read More Technical

Technical2018-07-19

How to check and prevent the spongy machine before use

In the process of production, we want to use sponge machinery to carry out a smooth and safe production. In mastering the correct operation methods and doing a good job of its daily maintenance, there are many problems to be paid attention to before the use of it. The sponge machinery factory will introduce it....

Read More Tehnical

Tehnical2018-07-19

The whole process and material of the production line of the sponge automatic production line

The automatic sponge production line is suitable for the continuous production of 8-80kg/cm3 density soft polyurethane sponge. It adopts a touch screen control system with high automation and more flexible operation. The user can store a variety of different formulas and can adjust the formula at any time, and can control the production cost through the Internet so as to make the production cost ...

Read More Technical

Technical2018-07-19

Causes and handling methods of sponge machinery failure during use

The reasons for the malfunction of the sponge machine in the process of use and the treatment method are the following problems: the overheating of the knife box, the serious vibration of the grinding machine, the buzzing of the cutter wheel, the serious cutting of the knife and so on....

Read More Technical

Technical2016-06-03

Specification for safe operation and maintenance of sponge cutting machine

Carefully check the performance and structure of the equipment before use to ensure the integrity of the components. The power switch, the tightness of the saw blade, blade shroud or safety baffle for detailed examination, operation must be steady, night work should have adequate lighting brightness....

Read More 技术支持

技术支持2016-06-03

How to determine the quality of sponge machinery?

Regeneration sponge machine is particulate sponge pulverizer suction suction box special good mixing cotton machine by mixing simultaneously injected into the corresponding weight of the sponge glue, and then use the mould (steam) pressed into the corresponding density of renewable sponge....

Read More Technical

Technical2017-04-29

Foam machine of the security measures

Now we all use the foam machine. Although the foam club is fun, but also good security measures. We one common method of protection is the use of a ground fault interrupter on devices that could come in contact with the foam. Visitors of foam parties also may attempt to protect personal electronic devices like cameras and mobile phones from the foam....

Read More Technical

Technical2017-05-02

Foam Rebonding Machine

The rebonded foam: a new product which is a sponge of the global common approach. The rebonded foam

belonging to the polyurethane products of industrial waste recycling.

...

Read More Technical

Technical2018-07-19

What are the main advantages of the regenerated foam machine?

In sponge processing industry, recycled foam machinery is often used. The main function of this kind of equipment is to inhale the smashed sponge particles into the special mixing box through the suction machine, and spray the corresponding sponge glue into the corresponding weight at the same time, and then press the mold (steam) into the corresponding regenerated sponge....

Read More Technical

Technical2018-07-19

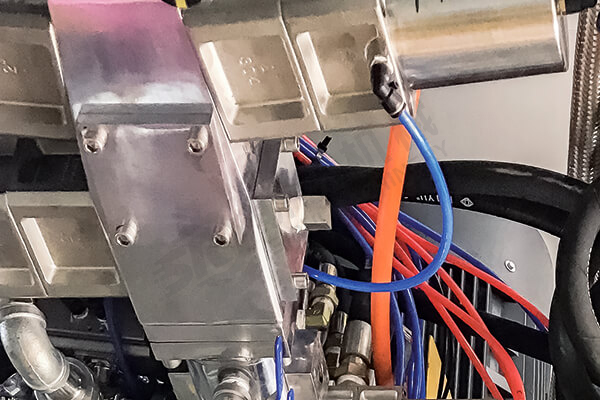

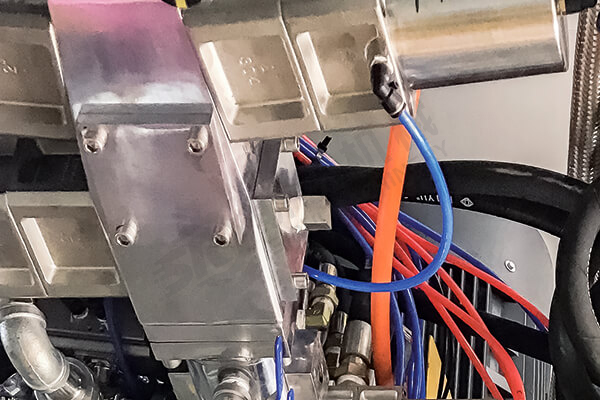

Characteristics of automatic sponge production line

The automatic production line of sponge is controlled by MITSUBISHI PLC and 12 inch large human-machine interface, making the control more convenient, free and visible. The use of MITSUBISHI inverter to realize the stepless speed regulation of various parts of the production line, with more freedom, making the production of sponge uniform, smooth, less waste, and easy to operate, easy to learn, ea...

Read More Technical

Technical2018-07-19

Detailed explanation of soft foam spongy box foaming process

After mixing the reaction material, it is poured into a wooden or iron case, which is made into the same open mold as foam molding, hence the name "box type foaming". The box type foaming mold (box) can be rectangular or cylindrical. In order to prevent the foam block from forming the arch round top, the floating cover plate can be set up on the top of the foam box. The cover plate is tightly atta...

Read More

Technical

Technical Technical

Technical Technical

Technical Tehnical

Tehnical Technical

Technical Technical

Technical 技术支持

技术支持 Technical

Technical Technical

Technical Technical

Technical Technical

Technical